The use characteristics of the busbar joint insulation protection box

Busbar connector insulation protection box: This product is also known as busbar protection box, busbar connector box, insulation box, protective sleeve, busbar insulation cover, connector protection cover, etc., with 1kv, 10kv and 35kv different voltage levels. For our company's first new product in China, after years of research and development, our company has finally developed the first domestic production equipment dedicated to busbar protection boxes and a related set of new production processes. Instantly changed the traditional backward production mode of the busbar protection box, so that the performance, appearance, and quality of the busbar protection box reached the international leading level, and the materials can be produced from polyolefin cross-linked, pvc, eva, pe, etc. including various composite materials Including busbar protection box products. Filling the domestic gap is a major highlight of national industry.

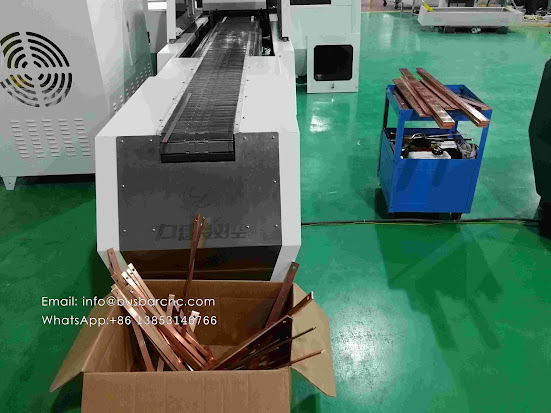

1 busbar bending machine manual. Product use: Mainly use the insulation protection of the busbar connector box at the connection of the live conductor of the electrical equipment, and the high and low voltage switchgear, circuit breaker, busbar connection, and the insulation protection of special parts such as transformer terminals.

2. Features of finished products: Irradiation can not reach the international leading level, and can produce busbar protection box products including polyolefin cross-linking, pvc, eva, pe and other composite materials. Filling the domestic gap is a major highlight of national industry.

1. Product use: Main deformation, no deformation when heated, no shrinkage when heated. The appearance is sharp and angular, the wall thickness is uniform, the size is accurate, the performance is stable, the appearance is smooth and meticulous, to the international advanced level, we can produce busbar protection boxes including polyolefin cross-linked, pvc, eva, pe and other composite materials product. Filling the domestic gap is a major highlight of national industry.

1. Product use: Main advantages such as long service life, can better show the equipment grade, and the overall effect is more obvious. For our company's patented products.

3. Compared with the disadvantages of the traditional busbar connector box protection box product: because the traditional busbar protection box is made by the heat shrinking process, the raw material is limited by the shrinkage ratio and its own elastic strength during preheating shrinkage. May be completely fitted with the mold, so the shape of the busbar box made is not good, the surface is rough, the shape is not in place, the heat will deform and distort, the size is not accurate, the thickness is uneven, the performance is unstable, the service life is short, the quality is poor, the insulation The degree of protection is difficult to reach the standard, and secondly it will affect the overall aesthetic effect of the equipment and reduce the grade of the busbar junction box equipment.

4. The specifications of applicable busbars are 30*3, 40*4, 50*5, 60*6, 80*8, 100*10, 120*12, 150*12, etc. The shape includes I type, straight T type and L type, and cross type. The colors are yellow, green, red, black and other common optional colors.

"T" type (the main bus bar and the branch bus bar are vertically overlapped)

"L" type (the main bus and the supporting bus are lapped at right angles)

"=" type (main bus and parallel bus are connected in parallel)

"+" type (cross-overlap of main bus and branch bus)