Problems in the installation process of dense insulated busbars

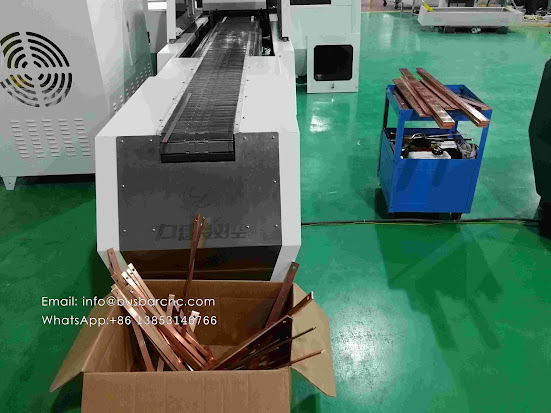

The dense insulated bus bar has the advantages of small volume, compact structure, large transmission current, safety, and convenient maintenance. It has been widely used in enterprise low-voltage distribution equipment. However, in the process of construction management, it was found that due to the monotonous product specifications of the manufacturer bus bar shear, the installation and operation manuals being too simple, and the design considerations, etc., it often caused on-site installation difficulties. The following are some issues that should be paid attention to during the installation of the dense insulated busbars from the transformer to the low-voltage distribution cabinet, for reference during construction.

1.) Connection of bus duct

Plug-in busbar connection. For the connection of the bus bar, use a high-strength insulation board with high insulation, arc resistance and flame retardancy as the connection accessory, and fasten it with a bolt with an insulation sleeve. According to the requirements of the specification, in order to meet the overlapping area of the busbar, the gap between the bolt hole and the bolt is small. Since the busbar bolt adds an insulating sleeve, the gap is narrower. Therefore, when the main busbars of the two sections of busbars are connected, the axis of the two sections of busbars should be kept strictly on a center line, and the busbars of the two sections of busbars and the bolt holes of the insulating plate should be completely aligned. When the bolts are tightened, each The bolts should be applied evenly in sequence. This purpose is to prevent the insulating sleeve on the bolt from being damaged by shearing force during installation. In the course of engineering construction management, the author found several cases of busbar insulation degradation due to the damage of bolt insulation sleeves. The grounding connection adopts the busbar shell to meet the grounding requirements. However, when all the busbar shells are sprayed, the two sections of busbar grooves must be connected with grounding bolts. The insulation of the bus duct should be checked before and after installation, and compared to check whether the insulation of the bus duct is reduced due to installation quality problems.

2.) Fixing method of transformer room bus duct

The bus bar provided on the manufacturer's sample is generally hoisted with round steel. This method is not suitable for the fixing of the bus bar in the transformer room. This type of hoisting is "flexible". It can only hold the bus bar to make it It can not move up and down, and when the busbar slot is improperly installed by twisting stress or under the influence of busbar short-circuit electromotive force, the busbar slot may sway to the left or right or up, which will cause damage to the transformer low-voltage bushing connected to the busbar slot Or oil leakage at the rubber seal at the root of the casing.

没有评论:

发表评论